ファイバーレーザーカッターは,製造業や金属加工業で使用される高度で効率的な機械で,精度と速度で様々な材料を切断します.ファイバーレーザーは、イタービウムなどの稀土元素でドープされた光ファイバーを使用して高強度光束を生成する固体レーザーの一種です。この技術は,レーザー切断の分野に革命をもたらし,より高いエネルギー効率,より高い切断速度,より幅広い材料を切断する能力を含む伝統的なCO2レーザー切断機より多くの利点を提供しています.

光ファイバレーザ切断機はどのように動作していますか。

光ファイバレーザ切断機の動作は、レーザビームの発生から始まる。光ファイバレーザ光源は光ビームを発生し、一連の光ファイバを介して切断ヘッドに伝送する。切断ヘッドは、切断すべき材料にレーザビームを集束し、高度に集中したエネルギー点を生成する。このエネルギーは材料を融点または気化点に加熱し、レーザを極めて高い精度で切断できるようにする。

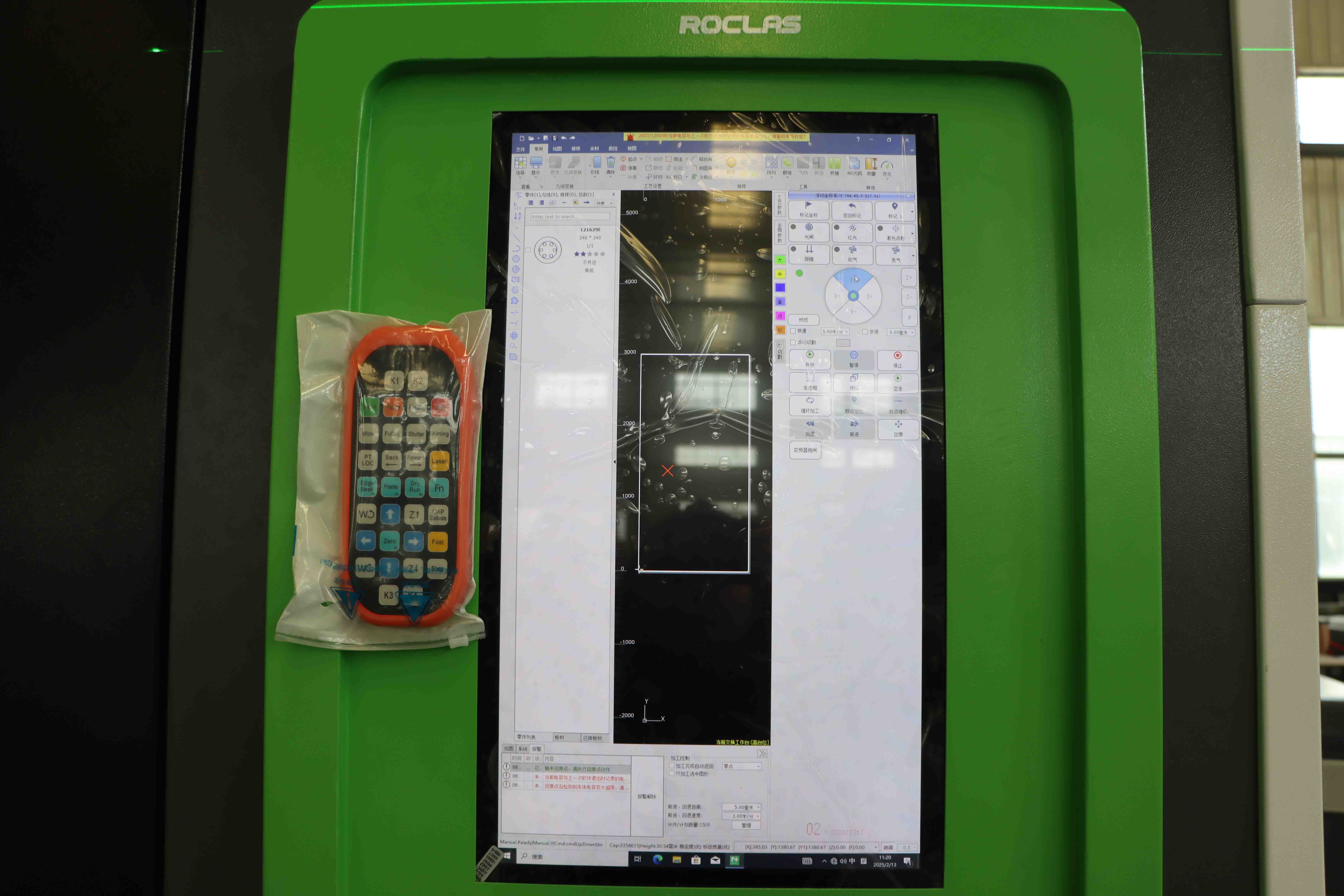

切断プロセスはコンピュータデジタル制御(CNC)システムによって制御され、切断ヘッドが所望の経路に沿って移動するように誘導される。CNCシステムはレーザーが設計の正確な輪郭に従うことを確保し、それによって清潔で正確な切断を実現する。プロセス全体が高度に自動化され、人手による介入の必要性が軽減され、エラーのリスクが最小限に抑えられます。

光ファイバレーザ切断機の利点

1.高精度と精度:光ファイバレーザ切断機は厳格な公差で極めて正確な切断を行うことができる。これにより、複雑な設計と詳細レベルの高いアプリケーションを必要とする場合に最適です。

2.高速切断速度:ファイバレーザの動作速度は従来の二酸化炭素レーザよりはるかに高く、切断タスクを完了するのに必要な時間を大幅に短縮した。この速度の向上は、より高い生産性とより低い生産コストに変換される。

3.エネルギー効率:光ファイバレーザは二酸化炭素レーザよりも省エネで、優れた性能を提供しながら消費電力が少ない。これにより、運用コストが削減されるだけでなく、光ファイバレーザ切断機をより環境に配慮することができます。

4.多機能性:光ファイバレーザ切断機は、金属(例えば、鋼、ステンレス、アルミニウム、銅)、プラスチック、さらにはいくつかのセラミックスを含む様々な材料を切断することができる。この多機能性は、自動車や航空宇宙から電子やジュエリーまで、さまざまな業界に適用されます。

5. Low Maintenance: Fibre lasers have fewer moving parts and require less maintenance compared to CO2 lasers. This reduces downtime and maintenance costs, ensuring that the machine remains operational for longer periods.

6. Compact Design: Fibre laser cutters are typically more compact than CO2 laser cutters, making them easier to integrate into existing production lines and reducing the overall footprint of the equipment.

Applications of Fibre Laser Cutters

Fibre laser cutters are used in a wide range of applications across various industries. Some of the most common applications include:

1. Metal Fabrication: Fibre laser cutters are widely used in the metal fabrication industry for cutting and shaping metal sheets and plates. They are particularly well-suited for cutting complex shapes and patterns in materials such as steel, stainless steel, and aluminum.

2. Automotive Industry: In the automotive industry, fibre laser cutters are used for cutting and shaping metal components, such as body panels, chassis parts, and engine components. The high precision and speed of fibre lasers make them ideal for producing high-quality parts with tight tolerances.

3. Aerospace Industry: The aerospace industry requires components that are both lightweight and strong. Fibre laser cutters are used to cut and shape materials such as titanium and aluminum, which are commonly used in the construction of aircraft and spacecraft.

4. Electronics Industry: Fibre laser cutters are used in the electronics industry for cutting and shaping components such as circuit boards, connectors, and enclosures. The precision of fibre lasers ensures that delicate electronic components are cut with minimal damage.

5. Jewelry Industry: In the jewelry industry, fibre laser cutters are used for cutting and engraving precious metals and gemstones. The high precision and detail offered by fibre lasers make them ideal for creating intricate designs and patterns.

6. Medical Industry: Fibre laser cutters are used in the medical industry for cutting and shaping medical devices and implants. The ability to cut with high precision and minimal heat-affected zones makes fibre lasers suitable for producing medical components that require strict quality standards.

Choosing the Right Fibre Laser Cutter

When selecting a fibre laser cutter, there are several factors to consider to ensure that the machine meets your specific needs:

1. Power Output: The power output of the fibre laser cutter determines its cutting capabilities. Higher power lasers can cut thicker and harder materials, but they also consume more energy. It is important to choose a laser with the appropriate power output for your intended applications.

2. Cutting Area: The size of the cutting area determines the maximum size of the material that can be cut. It is important to choose a machine with a cutting area that accommodates the size of the materials you will be working with.

3. Material Compatibility: Different fibre laser cutters are optimized for cutting different materials. It is important to choose a machine that is compatible with the materials you will be cutting.

4. CNC System: The CNC system controls the movement of the cutting head and ensures that the laser follows the desired cutting path. It is important to choose a machine with a reliable and user-friendly CNC system.

5. Maintenance Requirements: Fibre laser cutters require regular maintenance to ensure optimal performance. It is important to choose a machine with low maintenance requirements and easy access to replacement parts.

6. Cost: The cost of a fibre laser cutter can vary significantly depending on its specifications and features. It is important to choose a machine that offers the best value for your budget while meeting your specific needs.

Conclusion

Fibre laser cutters are a powerful and versatile tool that has transformed the field of laser cutting. With their high precision, fast cutting speeds, and energy efficiency, they offer numerous advantages over traditional CO2 laser cutters. Whether you are working in the metal fabrication, automotive, aerospace, electronics, jewelry, or medical industry, a fibre laser cutter can help you achieve high-quality results with minimal effort. By carefully considering the factors outlined above, you can choose the right fibre laser cutter for your specific needs and take your production capabilities to the next level.

一般的なアドバイスが必要であれ、具体的なサポートが必要であれ、喜んでお手伝いします。